- +86 13837949030 +86 15890619536

- info@lymcbearings.com export@lymcbearings.com

- Luoxin Industrial Cluster, Luoyang City,Henan Province,China

Time:2025-12-05 07:51:41 Source:LYMC Slewing Bearing

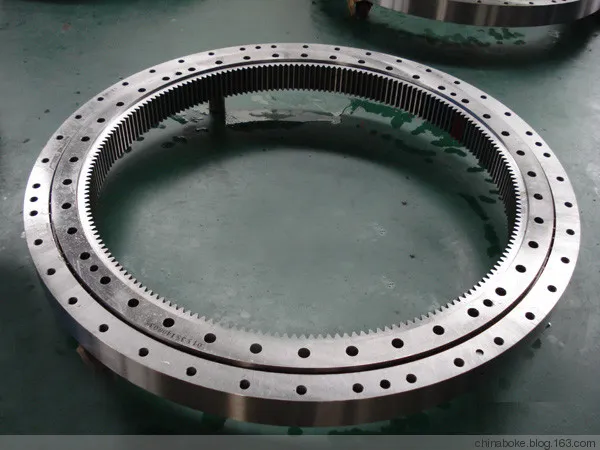

Slewing bearings are core rotating components in construction machinery, lifting equipment, wind turbine generators, and large machine tools, and their performance directly affects equipment safety and production efficiency. However, tooth breakage is a frequent problem after long-term use, leading not only to equipment downtime but also potentially high maintenance costs. So, why do slewing bearings break teeth? And how can this be prevented scientifically? This article will provide a systematic analysis.

1. Overload Operation

Slewing bearings are designed with a rated load range. Overloading causes stress concentration on the tooth surface, accelerating material fatigue and ultimately leading to tooth breakage. This is especially true in cranes or large excavators, where improper operation poses a very high risk of overloading.

2. Improper Lubrication

Insufficient lubrication or low-quality lubricating oil leads to direct metal-to-metal contact between the tooth surfaces, increased friction, localized temperature increases, and rapid gear wear. Neglecting lubrication maintenance over a long period is a major cause of tooth breakage.

3. Installation and Adjustment Issues

The installation accuracy of the slewing bearing directly affects the gear meshing state. Uneven installation or preload can lead to uneven gear stress and excessive localized stress, easily causing tooth surface damage or even tooth breakage.

4. Material and Heat Treatment Defects

Inadequate strength, hardness, and surface treatment of gear steel can easily cause micro-cracks under high stress environments, eventually leading to tooth breakage due to long-term accumulation. Uneven carburizing or insufficient quenching are also common hidden dangers.

5. Harsh Operating Environment

High temperatures, dust, and corrosive media can accelerate tooth surface wear or corrosion, reduce load-bearing capacity, and increase the risk of tooth breakage.

1. Strict Load Control

Ensure equipment operates within its design load range and avoid frequent overloading. For high-load machinery, slewing bearings with higher rated loads can be selected to increase safety margins.

2. Optimize Lubrication Scheme

Use lubricating grease that meets specifications and regularly check the oil level and quality to ensure adequate lubrication of the tooth surface. For heavy-duty or high-speed operating equipment, consider a circulating lubrication system to improve tooth surface protection.

3. Improve Installation and Commissioning Accuracy

Install the slewing bearing strictly according to the manufacturer's standards, ensuring concentricity between the base and the drive unit, and uniform preload. After trial operation, check the gear meshing and adjust promptly.

4. Select High-Quality Materials and Heat Treatment Processes

Prefer high-strength alloy steel, ensuring a reasonable heat treatment process, uniform hardness, and toughness. If necessary, perform surface strengthening treatment on the tooth surfaces to improve wear resistance and fatigue resistance.

5. Improve the Working Environment

Minimize the erosion of the tooth surfaces by dust, moisture, and corrosive media. Install protective covers, clean regularly, or apply anti-corrosion coatings to extend the slewing bearing's lifespan.

As a critical load-bearing component, the issue of tooth breakage in slewing bearings cannot be ignored. From overload use to lubrication management, installation accuracy, and material selection, every aspect can become a risk point. Through scientific operating procedures, regular maintenance, and the selection of high-quality materials, the incidence of tooth breakage can be significantly reduced, improving equipment operational stability and production efficiency.

Pay attention to details; prevention is better than repair. Proper slewing bearing management not only ensures smooth production but also saves companies significant maintenance costs, making it an essential operating principle for every equipment manager.